hinge notebooks

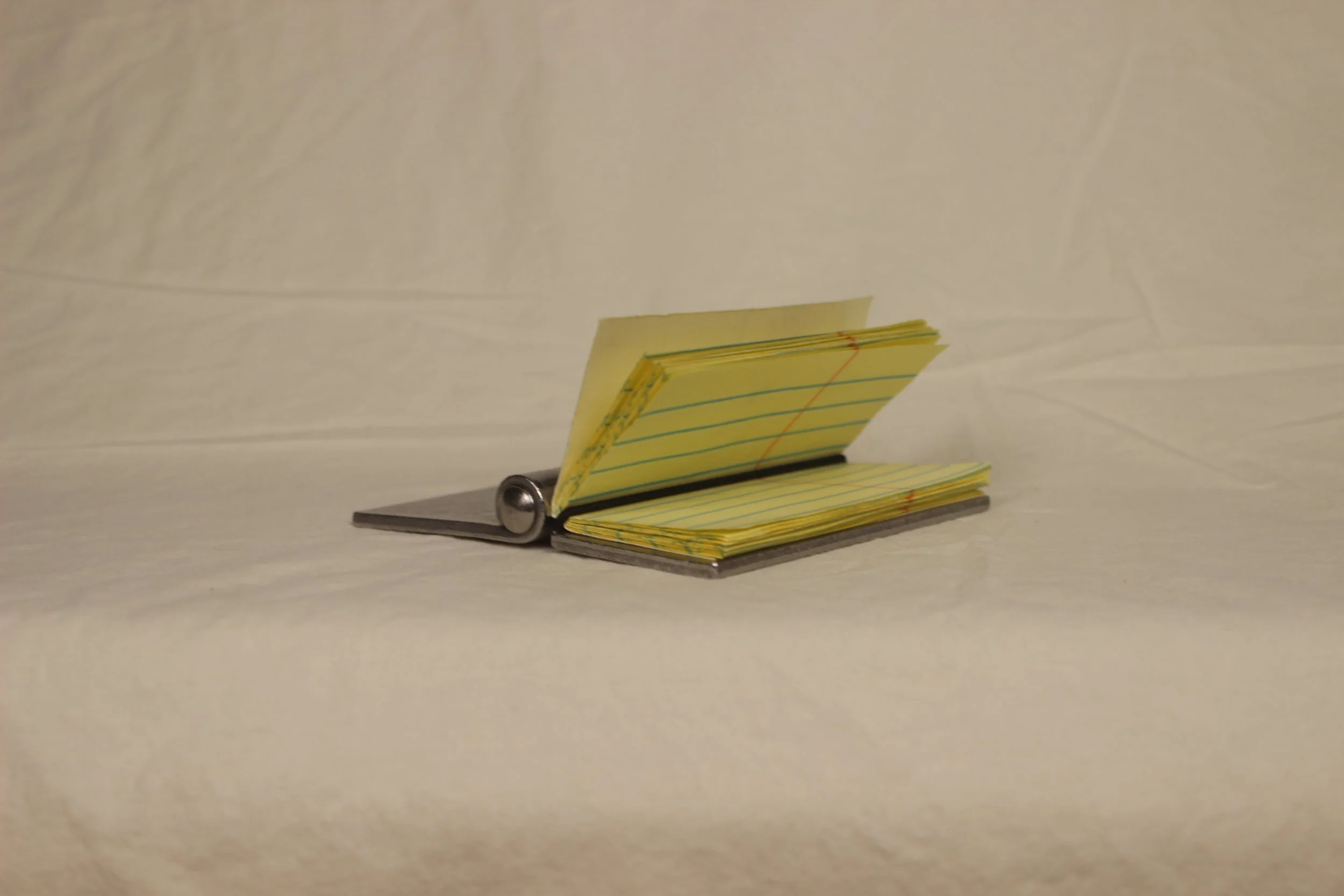

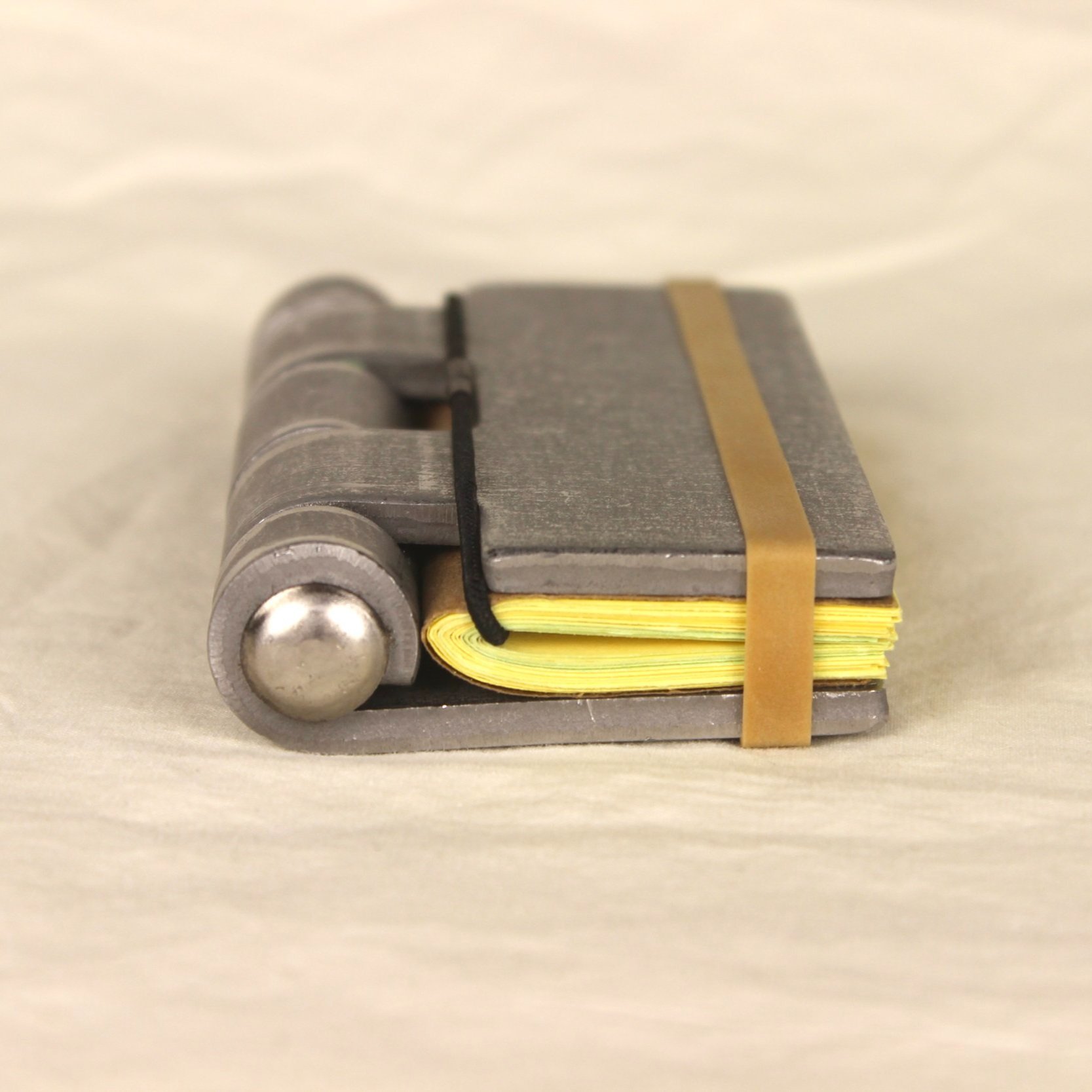

I was standing in the shop at my childhood farm looking at a hinge, holding it in my hands, opening it, closing it. This focus on the parts that make such a movement possible stuck with me, and I kept wondering. I had an idea! I had been making journals and notebooks before this, and I realized this hinge was a cover. It was two ends of a book with a joint right down the spine. I had a legal pad in my drawer, and I got to work. The paper is cut to size and trimmed in groups to allow for a flush edge. I use elastic cord to wrap the paper around the spine, and wire shrink tubing join the ends. Recycled paper bags are cut for an inside cover to allow for more integrity.

The yellow of the legal pad paper next to the steel was a stunning combination to me, both visually and metaphorically. All welding hinges are bought secondhand, so paper must be cut to size different each time. This is not a streamlined process, by design. The extra time taken to cut to unique sizes allows for something old to be made new. Giving a tool a unconventional use; something industrial to be made soft. Re-use is an vital and underutilized process in our current production cycles and the creation of goods. And you can still weld this hinge